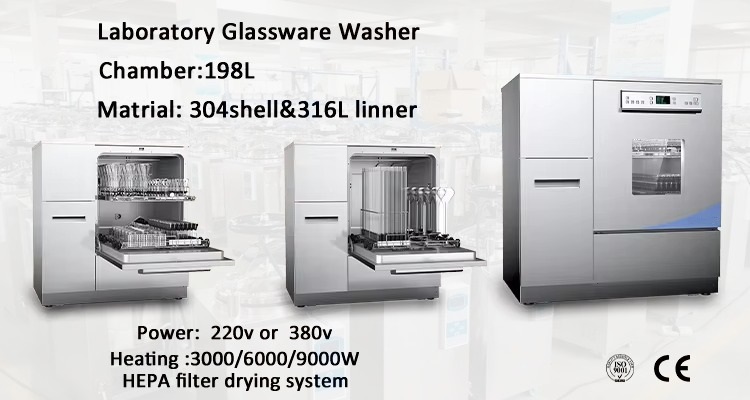

Laboratory Glassware Washers and Dryers Manufacturer/Pharmaceutical appliance washer/220L Automatic SS316 Laboratory Glassware Washer with Drying / Glass washer and cleaner/Laboratory Medical Automatic Glassware Washer Cleaning and Sterilizing Machine

Lab glassware disinfector Washer is manufactured according to the technical specifications established by the latest technology, following the guidelines of the International Quality Standards. The Laboteck Lab Glassware Cleaning Machine is an automated, micro-processed unit for cleaning, washing, thermal and/or chemical disinfection, and drying of surgical instruments, vats, trays, laboratory glassware, and breathing and anesthesia tubes.

Laboteck Laboratory Glassware Washers have several models that meet any type/volume of cleaning and washing, occupying little space and with great cost-benefit. Some of the most significant characteristics of these washers are the large production capacity occupying little external space, ergonomics, ease of handling, control, and registration through industrial microprocessors, and the vertical washing and cleaning pump system.

Application scope : Glassware washer applied to many applications like cleaning, sanitization, sterilization and drying of various types of glassware’s. It is generally used in pharmaceutical laboratories, production departments, research and development centers, disease control units, Food Industries, Chemical manufacturing units & electronic companies.

Standardized Cleaning:

1. Standard cleaning with complete angular spraying of 360 degree, never leaves dead angle & provide cleaning effect.

2. There are two water inlet points regulated by electromagnetic valves, user can select the tap water and distilled water during washing and rinse.

3. Water inlet point has water booster pump that directly consume pure water without any external pump.

4. This machine is equipped with all kind of safety parameters like too much of water in chamber will stop working after alarm and release the water from drain point immediately. No back flow of water from drain point as it has water sealing design.

5. Audio and visual alarms for shortage of cleaning agent, overflow, drainage and lack of water supply.

Filter system:

- Yatherm Glassware washers has SS 304 filters that protects recirculation & drain pumps from any kind of damage.

- Filters are fixed at the point of air intake.

- Incoming point of water are also covered with filters.

- Filters are made of SS 304 so it can be cleaned, removed and fixed any time.

Dual peristaltic pumps(detergent & Neutralizers) Complete Sanitation of glassware’s becomes more effective if washing and neutralization of treated material is correctly performed. This process is possible with two peristaltic pump only as it dispenses the alkaline detergent during the cleaning phase. Acid neutralizers’ makes the cleaning , washing and neutralization much more effective.

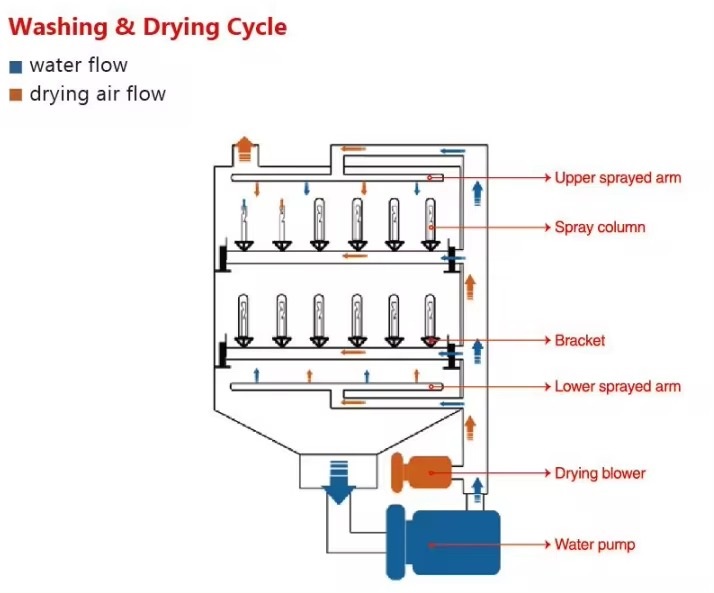

Fully automatic operation makes the laboratory glassware washer much more effective with less human interference. Peristaltic pump works as per the program, separate sensors allow to draw a set amount of liquid detergent during the washing cycle. Cleaning chamber has two washing arms, one is upper and second is lower and both the arms operates with rotary speed monitor device.

Drying system: We use most innovative technology that makes our equipment different from other brands. Hot air drying helps in drying the glassware’s from every corner with 360 degree no dead end angle. The Forced air drying process leave no scope for long term moisture and sterilizes utensils at high temperature. High performance rapid air drying system consist of hot air generator and powerful fan operated by Microprocessor based PLC.

Digital Control panel equipped with PLC/HMI that controls preset programs, operating time, temperature parameters, adjustment of fan speed & drying period. Temperature range can be set up to 120 degree Celsius which improves the sanitation, washing and rinsing of glassware’s.

Humanized operating system

1. 4.3 inches and 7 inches color touch panel has programmable logic controller with easy to use operation, real time animated working display & pressure sensing feature.

2. PLC and HMI are designed only for complex operating system with easy operation. it is reliable, stable, accurate, anti-magnetic, self diagnosis and safe with three levels of password protection.

3. Control panel has many features like water type, cleaning time, drying time, water intake , water overflow, cleaning agent add, fan speed control & drying time.

4. it has Data logging function can store up to 1000 of parameters. Power off memory feature makes it fully automatic and no need of human interference in case of power supply interrupt.

5. LCD touch panel with real time operation, real time graph , real time data logging , operating procedure & standard working parameters.

Microprocessor Control System

- Color Touch panel with 7 inches display

- Water level and water injection system can be controlled.

- Microprocessor based PLC

- Washing cycle

- Detergent volume selection

- 100 programs

- Program execution time

- Working temperature range

- Type of Water

- Volume of water

- Three level Password Protection

- Water Pumps recirculate water to remove contaminants via cleaning process

Cleaning program: YSK-LW320/220/120 has 10 factory set programs for cleaning and rest of the programs can be set by user. These cleaning programs has different types of washing steps like washing, pre-wash, water supply, acid rinse, hot water cleaning, acid naturalize washing & drying. Single program of cleaning can set a washing time, volume of detergent, hot water temperature, drying temperature & drying time.

System wash levels

- Three levels of washing.

- Automatic manifolds connection at all washing levels

- Easy to remove and Easy to fix in all models

- Cleaning of racks at all washing levels

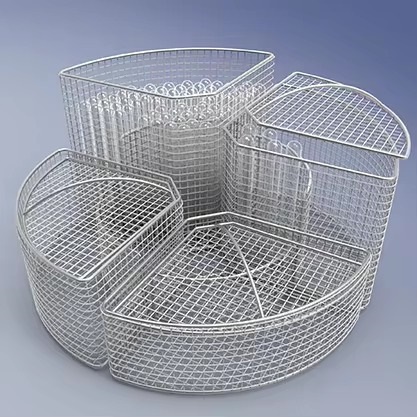

Optional accessories :

- Water conductivity monitoring system

- Water hardness monitoring system

- Sensor detects dissolved inorganic ions like ferrous , calcium and magnesium in water tank

- Glassware holders Like Round bottom flask, Beakers, Petri dishes & bottle holders.

- Printer provides detailed report on complete washing, drying and rinse process.

LAB GLASSWARE CLEANING MACHINE KEY FEATURES:

Automated unit for washing, disinfection, and drying term labware, glassware, and various materials, micro-processed, programmable, built-in stainless steel, and brand models.

LABORATORY GLASSWARE CLEANING MACHINE CHARACTERISTICS:

- Construction in stainless steel – high strength and precision;

- High-capacity pumps provide powerful and economical cleaning and washing, with controlled pressure to prevent breakage of glassware, which attests to the quality and reliability of products;

- Time and money savings – washers consume about 30% less water than the competition and washing and drying cycles are up to 35% faster;

- Individual pumps for cleaning, dispensing, draining, and valve and filter systems guarantee a safe and efficient cleaning/washing, without risks of cross-contamination and effluent reflux;

- Integrated vapor condensation system – prevents the release of vapors and odors into the laboratory environment and speeds up the drying process of the glassware;

- Security system with double temperature sensor, dispensing sensors, water inlet, speed of the rotating arms, condensation and flood prevention system – total control and security of the cleaning cycle, with error messages on the display;

- New washing module system – even more flexible than the previous generation;

- Possibility of rinsing the material with distilled/deionized water;

- Water heating up to 5x faster than the competition, up to 93 ° C;

- Integrated water softening system;

- Models of laboratory washing and disinfecting machine available with active drying up to 115 ° C, with HEPA filter at the air inlet;

- Pass-through models available, ideal for clean rooms;

- High versatility – several types of baskets, supports, and accessories available;

- Models with the possibility of free installation or under the bench;

- Laboteck Labware Cleaning Machine is designed to work over 15,000 hours without maintenance on pumps and mechanical parts;

| Model | YSK-LW120 | YSK-LW220 | YSK-LW320 | YSK-LW420 |

| Capacity | 120L | 220L | 320L | 420L |

| Water Consumption/Cycle | 15L | 25L | ||

| Inlet Water Pressure | 0.03~0.8Mpa | |||

| Noise | ≤50dB | ≤55dB | ||

| Material | Internal Material: SS316, Outer material: SS304 | |||

| Overall Power Consumption | 6KW | 6.5/16.5KW | 6.5/18KW | 18kW |

| Power Consumption-Water Washing | 0.75KW | 1.5 KW | 2.8KW | |

| Power Consumption-Water Heating | 5KW | 5/15KW | 15KW | |

| Power Consumption-Drying | 2.1 KW | 3.6KW | ||

| Power Supply | AC220V, 50Hz | AC220V, 50Hz; 380V, 50Hz | 380V, 50Hz | |

| Cleaning Racks | 1 pcs | 2 pcs | 3 pcs | 2 pcs |

| Standard Cleaning Racks | BKIR36*1 | BKIR36*2 | BKIR36*3 | BKIR36*2 |

| Standard Accessories | One bucket RBS A 155 leaner (1 L), One bucket RBS A 375 neutralizer (1 L) | |||

| Optional Accessories | USB interface, printer, Cleaning racks | Cleaning racks | ||

| Washer Chamber Size(W*D*H) mm | 600*629*465 | 600*629*658 | 600*629*820 | 688*700*703 |

| External Size(W*D*H) mm | 960*740*850 | 780*690*1760 | 790*690*1950 | 1100*900*2165 |

| Package Size(W*D*H) mm | 1100*950*1050 | 1000*850*2100 | 1000*840*2180 | 1270*1025*2240 |

| Gross Weight(kg) | 145 | 330 | 350 | 400 |

WHY CHOOSE LABOTECK?

Laboteck Lab Glassware Disinfector Washers are considered a world reference in the cleaning, washing, and disinfection of glassware and laboratory materials. With several years’ experience in the distribution of laboratory equipment. All Labware Cleaning Machine Washers have stainless steel cleaning/washing chambers. The equipment is completely configurable, with accessories for washing Becker, Erlenmeyer flasks, pipettes, beakers, everything for testing, volumetric flask, etc. Laboteck, a branded firm has professionals with several years of expertise in the field of laboratories, education, medical-hospital, and pharmaceutical industries solutions in equipment derived from the latest technology and brand products with its high quality, high durability, and low maintenance products.

Request A Free Quote