Lab Planetary Ball Mills With ordinary stainless steel jar & ball/ Soil Grinding Laboratory Planetary Ball Mill for metallurgical technology/ Laboratory Planetary Mini Ball Mill For Fine Grinding/ 2L 4L 6L 8L 20L 40L Lab Planetary Vertical Ball Mill Machine 4 Jars/ laboratory Planetary ball mill suitable for nano-grinding.

The work carried out within the laboratory and production environment needs the support of a diversity of products, materials, accessories, and laboratory and industrial equipment. Planetary ball mills are responsible for the material grinding and micron size mixing process, but each has specific characteristics, and therefore, they apply to different purposes. The planetary ball mill is equipment designed with a high technological standard that makes it possible to automate grinding processes and optimize the productivity index, including repeating exact results.

It is the ideal equipment for grinding dry and/or wet, hard, medium hardness, soft, fibrous, brittle, and wet samples and also for mechanical alloys, mixing and homogenizing large quantities of samples with reliable results. With an automatic system, the planetary ball mill is totally safe due to the technology employed and the exclusive locking mechanism of the grinding vessels.

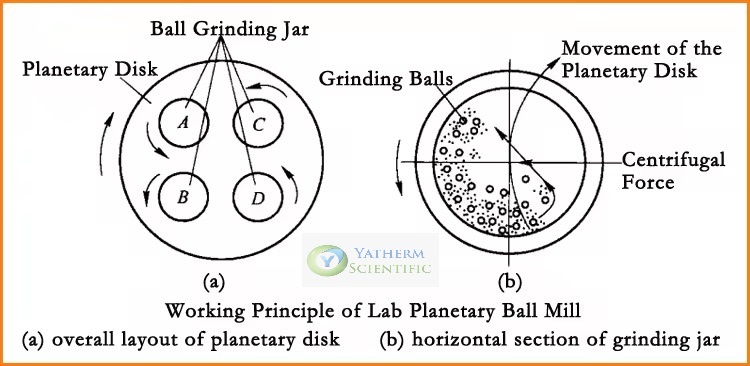

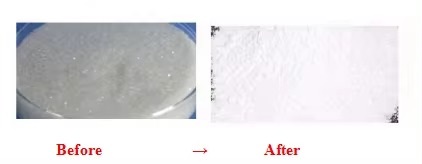

Planetary ball mills are used whenever it is necessary to obtain maximum fineness. In addition to the classic mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and provide sufficient energy for the mechanical preparation processes of mechanical alloys. The extremely high centrifugal forces of planetary mills result in extremely high spray energy and, therefore, short grinding times. at Laboteck, vertical and horizontal planetary ball mills can be found in different capacities and options ranging from 2 liters to 16 liters for laboratory use and 20 to 100 liters for production use.

TECHNICAL ASPECTS OF PLANETARY BALL MILL

The planetary ball mill is a high-energy type mill that can be manufactured in several models for laboratory and production uses, in order to meet the specifications of certain applications. In general terms, its use is restricted to the work of reducing the sample size in milling processes. To achieve this reduction, the planetary ball mill performs a combination of high-energy impact and friction effects of the spheres on the samples within the grinding vessel.

SPECIFICATIONS & FEATURES:

- Types: Vertical and Horizontal

- Volume: 2 to 16 Liters (For Laboratory Use) & 20 to 100 Liters (For Production Use)

- Speed (Fast Grinding): Up to 670 RPM

- Power Supply: 220 Volts 50Hz

- Feed: Soft & Crispy Material ≤ 10mm & Other Hard Materials ≤ 3mm

- Granularity: Minimum <1 µm (Depending On Material)

- Time: 1-9999 Min

- of Jar: 4 (Grinding or Mill Jars Available)

- Up to 4 Grinding Stations Simultaneously

- Sample Type: Hard, Soft, Fibrous, and Brittle.

- Powerful and Fast Grinding

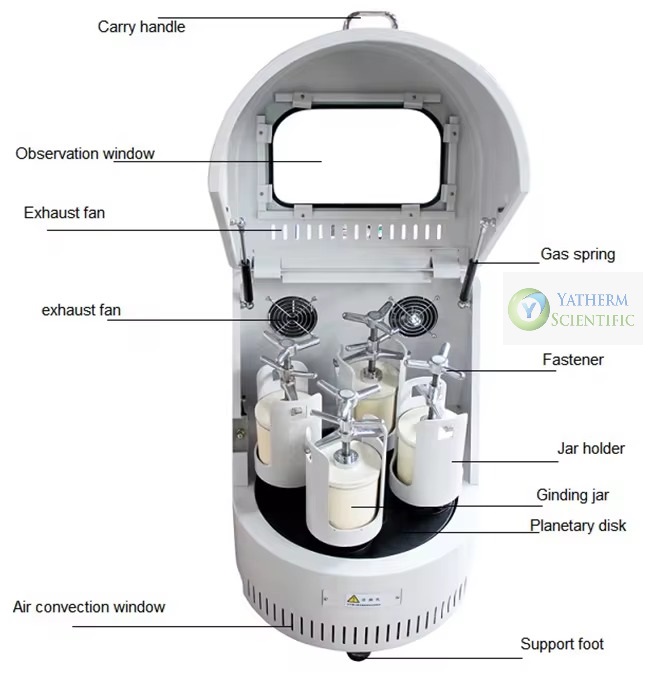

- Automatic Ventilation System for the Grinding Chamber

- Diversity of Materials: Stainless Steel, Agate, Zirconium Oxide (Zirconia), Tungsten, & Synthesized Aluminum Oxide (Alumina)

- Variety of Accessories Available

- High Safety Performance

Laboteck Offered Models

- Vertical Planetary Ball Mill (Semi-circle Type) – 3D curve shape design.

- Vertical Planetary Ball Mill (Square Type) – Special gear with low noise.

- Light Horizontal Planetary Ball Mill – Horizontal structure of grinding pots.

Technical Specification :

| Model | VENUS – 0.4 | VENUS – 1 | VENUS – 2 | VENUS – 4 | VENUS – 6 |

| Capacity | 0.4L | 1L | 2L | 4L | 6L |

| Volume Range | 50ml-100ml | 50ml-200ml | 50ml-500ml | 250ml-1000ml | 500ml-1500ml |

| Feeding size | Soil≤10mm ; Others≤3mm | ||||

| Output size | ≥0.1um | ≥0.1um | ≥0.1um | ≥0.1um | ≥0.1um |

| Power (kw) | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Voltage | 220V50Hz | 220V50Hz | 220V50Hz | 220V50Hz | 220V50Hz |

| Revolution Speed (rpm) | 35-335 | 35-335 | 35-335 | 35-335 | 35-335 |

| Rotation Speed (rpm) | 70-670 | 70-670 | 70-670 | 70-670 | 70-670 |

| Weight(KG) | 90 | 100 | 105 | 110 | 130 |

| Dimension (mm) | 700x570x520 | 700x570x520 | 700x570x520 | 700x570x520 | 700x570x520 |

AREAS OF APPLICATION:

APPLICATION EXAMPLES:

Metal oxides, compound fertilizer, garbage samples, bentonite, hair, limestone, active carbon, catalysts, kaolin, cellulose, ceramics, cement clinker, coal, concrete, coke, slag, fibers, carbon fibers, plaster, hydroxyapatite, alloys, effluent sludge, wood, iron ore, ores, minerals, clay minerals, bones, paper, plant parts, pigments, polymers, chemicals, quartz, seeds, semi-precious stones, soil, electronic scrap, tobacco, fabrics, paints and varnishes, glass and more.

WHY CHOOSE PLANETARY BALL MILL FROM LABOTECK?

With extensive expertise in measuring instruments and laboratory equipment associated with the latest technological innovations and the highest standard of quality and reliability of results, Laboteck offers high precision solutions that reveal the latest trends in the technological market. In addition to providing technical assistance for all equipment. If you are looking for a high-performance Planetary Ball Mill at a competitive price, you can find it on the website of Laboteck.com, list products with our professionals, and get to know the best reference in quality in the Indian market today. We encourage you to contact us to discuss your requirements. We are looking forward to the dialogue with you! Make your free quote right now!

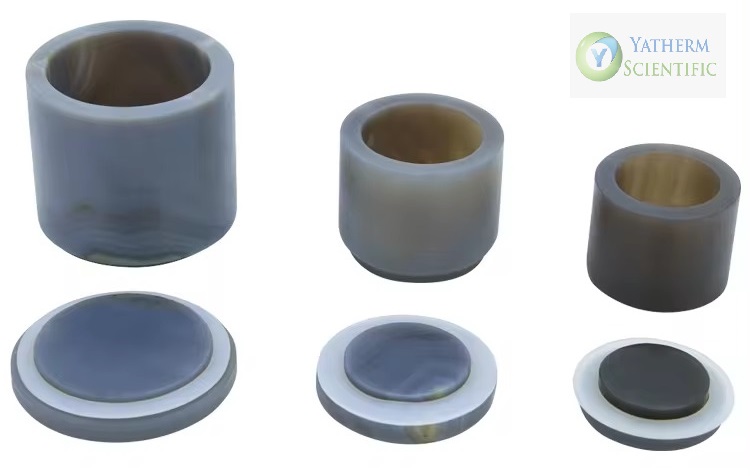

Optional Accessories: Jars and Balls

We have multiple jar material options : Pots are designed in such a way that pots material leaves no polluting content to the grinding materials and it leaves no effect to the appearance of output. Quality Jars for Planetary Mill like Zirconia jar, Nylon Jar, PTFE jar & Stainless steel Jar.

Technical Parameters:

| Category according to Grinding Material | Suggested Mill Pots’ Material |

| Soil & Materials in which impurities are not allowed. | Agate Pot |

| Metals and non-metal materials in which impurities are not allowed. | Zirconia Pot |

| High hard materials & hard alloy. | Hard Alloy Pot |

| Strong acidic and strong alkaline substances, and materials w/ high temperature. | PTFE Mill Pot |

| Steel Material with lesser impurities | 304 Stainless Steel Mill Pot |

| Pigmented samples that can be operated at high temperature. | Nylon Mill Pot |

| Ceramic glaze & aluminum based products. | Corundum Pot |

| Electronic components & Li3+ ion batteries components. | Polyurethane Mill Pot |

| Material that can be easily reacted in atmosphere needs inert atmosphere. | Vacuum Mill Pot |

High Quality Balls : High Quality Material balls like Stainless steel balls, Alumina Balls, Agate balls & iron core PU ball. Balls are offered according to the jar capacity and requirement of customers.

Request A Free Quote