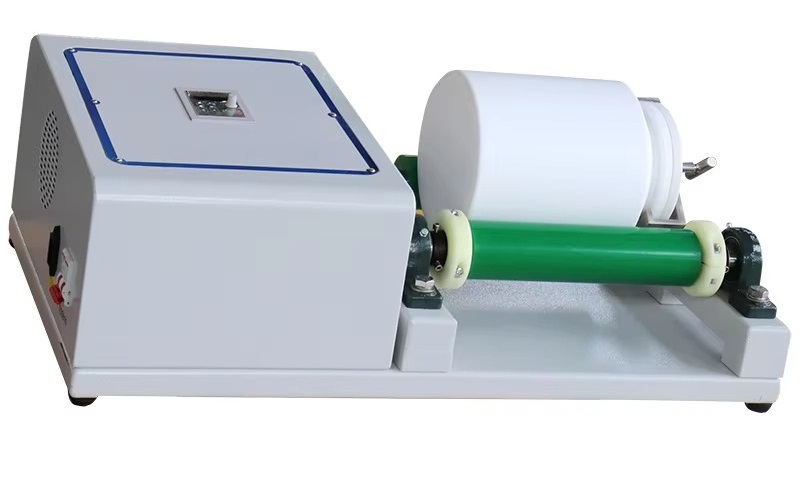

Uncover the Unparalleled Grinding Performance with Our Roller Pot Mill/ High Efficient Jar Milling Machine / Drum Ball Grinding Rolling Machine Roll Pots Jar Machine/ 4-5L Pots Lab Rolling Ball Mill Price/ Lab Roller Jar Mill

One of the most important factors of any successful and efficient powder processing, depends on the accuracy of the particle size control.

At Laboteck, we have a total understanding about the essential role a top notch roller pot mill contributes in the whole process. That’s the reason we have flawlessly constructed our roller pot mill to offer tremendous function ability, extraordinary reliability and remarkable flexibility.

Application of Roll Pots Jar Machine

Rolling out The Power of Our Roller Mill: Features of the Product

Our roller pot mill is more than just another tool which you can buy from anywhere, it’s a uniquely articulated long lasting partner especially made to enhance your productivity. Here are some of the important features that will help you reach heights in the business world:

● Unparalleled Grinding Effectiveness: Our Roller Pot mill is built to display maximum strength and efficiency. It will give you all what you need to pulverize the materials to required size while producing almost negligible waste.

● Perfect Adaptability towards all Types of Materials: Our roller pot mill is useful in grinding many different types of materials including dry materials like medicinal ones and cosmetics. Its versatility will fit your production facility very well.

● Accurate Control, Consistent Performance: Our user-supportive operator interface helps you in controlling the roller speed, input rate and interval, as per your necessity. This makes sure that you have uniformity in particle size and top quality results.

● Manufactured for Long Lasting Performance, Designed for Security: We put durability and user security as our top priority. Our roller pot mill is manufactured with top quality substances, making sure to provide you a long term performance and to stay firm in demands of high pressure production atmospheres. Other than that it is also loaded with special safety features to provide protection during the operation, giving the workers a peace of mind while performing the task.

● Easy to maintain which offers 24×7 Operation: We know how important it is for you to keep the production line going flawlessly. Our roller pot mill is manufactured in such a way that you will need very less time and effort for its maintenance. Not only this, but because of the unique design and presence of easily available components, your time in cleaning and replacement will be reduced to minimum and your functionality will be at the maximum.

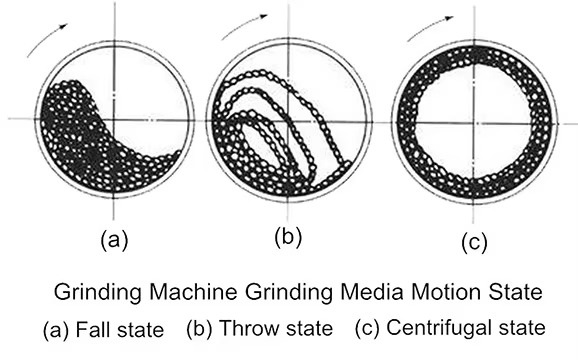

Working Principle of Pot Mill :

When Pot mill works, the grinding media like balls and the materials inside the Jar are rotated to a certain height clockwise. Due to the impact of the gravity, material and balls fall down from the Jar wall. Materials are crushed by falling impact action of the balls, friction between balls and material and shearing action of grinding media’s rolling and sliding.

Presenting the Specifications: A Technical Analysis

For those who want to have a detailed understanding, here’s a technical layout of our roller pot mill’s specifications.

● Feed particle size: It can be 5mm ( totally changeable depending on the type of model)

● Micron Size Particles: As precise as 10 microns ( which depends on substance and internal structure)

● Production capacity: It varies from the small scale production to mass production line (model based)

● Roller Substance: Corrosion- resistant steel which offers you perfect resistance from wear and tear as the time passes.

● Motor Capacity: It depends on the version of the model and required capacity.

● Automation system: PLC-controlled for accuracy and easy to use system which is perfect for users.

● Security Features: PLC-controlled for accuracy and user centered design which is easy to operate.

|

Model

|

Pot-Q-1

|

Pot-Q-2

|

Pot-Q-3

|

Pot-Q-5

|

Pot-Q-10

|

Pot-Q-15

|

|

Jar Volume(L)

|

1

|

2

|

3

|

5

|

10

|

15

|

|

Sample Capacity per time (L)

|

0.3L

|

0.7L

|

1L

|

1.7L

|

3.3L

|

5L

|

|

Power (W)

|

400

|

400

|

400

|

400

|

750

|

750

|

|

Rated Voltage(V)

|

220

|

220

|

220

|

220

|

220

|

220

|

|

Maximum Load (KG)

|

8

|

10

|

20

|

35

|

50

|

80

|

|

Speed Mode

|

Frequency Conversion Speed Regulation

|

|||||

|

Rotation Speed (r/min)

|

60-570

|

60-570

|

60-570

|

60-570

|

60-570

|

60-570

|

|

Size(mm)

|

730*415*260

|

730*415*260

|

730*415*260

|

730*415*260

|

840*435*270

|

840*435*270

|

|

Station Space (mm)

|

260

|

260

|

260

|

260

|

340

|

340

|

|

Roller Distance(mm)

|

120

|

120

|

120

|

120

|

140

|

140

|

|

Tank Material

|

Ceramic, Stainless steel, Corundum, Polyurethane, Nylon, PTFE, etc.

|

|||||

|

Medium Ball

|

Alumina, Zirconia, Agate, Hardened steel, Stainless steel, etc.

|

|||||

|

Remark: Loading rate of ball mill can not exceed 70% of the effective volume of grinding cylinder.

|

||||||

Are You Ready to Discover the Power of Fine Grinding?

At Laboteck, we are absolutely dedicated to enhancing your powder technology competence.

Our Roll pot mill is more than just a tool, it’s a commitment to excellence, effectiveness and constant function ability.

Grab the Opportunity Now!

Talk to us now, and get a free consultation, under no compulsion to buy anything.

We will thoroughly discuss your precise grinding requirements and suggest you the suitable roller pot mill configuration to enhance your manufacturing belt to higher levels.

Let’s unleash the great potential of meticulous grinding with each other!

Optional Accessories