Autoclavable bags/ High temperature resistant Biohazard bags/ Autoclave bags for steam sterilization/ Hospital Clinical autoclave waste bags

Quality Autoclave Sterilization Bags:

The autoclave sterilization bag, also called the discard bag, is a type of packaging developed for the previous isolation of biological source, infectious or biohazardous waste in the sanitation process, for later disposal.

The use of the autoclave sterilization bag is essential for the safe disposal of this type of material, sometimes the residues can be toxic and harmful to the contact, so that when isolated do not pose risks to the environment or human health.Autoclave bags are used in the decontamination process for later disposal, promoting inactivation of microorganisms and removal of residues in glassware, consumables and other autoclaving resistant laboratory products. Single use product in autoclaves.

Autoplate Packing Is Essential To Keep Sterilization of the Protective Equipment And Product:

Any commercial packaging must primarily protect the equipment to which it is applied. Based on this principle and in the specific case of autoclave packaging bag, one of the main highlights of this use is the complete sterilization that only this product is capable of generating to the different materials it protects. First of all, it is quite natural that the autoclave packaging bags, precisely because of this feature, is widely useful in the hospital environment and others.

As a practical example, it is common for polypropylene autoclave packaging to be widely used in scalpel guards and other surgical equipment precisely because of the full protection that the equipment can provide for these materials. Offering a high resistance against bacteria, the polypropylene autoclave packaging can also be applied in the operating room’s own hospital spaces or any other environments present in these spaces.

When it comes to the technical specifications behind the manufacture of autoclave packaging bags, another important differentiation of the product is the materials in which it can be coupled. In paper or film, it is possible that the packaging offers practical and very functional and safe results to the equipment to which it is integrated.

Laboteck is a leading provider of sterilization products and Autoclave Packaging Bags. It works with hospitals, medical, dental and veterinary clinics, as well as the pharmaceutical, cosmetic, automotive, aerospace petrochemical and agriculture industries.

Features & Advantages:

- The autoclave bags used as a “waste bin” are intended for the prior “inactivation” of laboratory waste disinfection by autoclaving at 121°C, 135°C and 141°C for later disposal.

- High temperature resistant.

- Autoclave bag made of HDPE (High Density Polyethylene), milky. Made by welding on the sides of the bag for greater safety in the use of the product. Made using as raw material transparent high density polyethylene.

- Red, Yellow and Clear (transparent) colors are available.

- Any size from small, medium, large to extra-large are available.

- Exclusive use for autoclaving / decontamination.

Autoclavable Bags Sizes

| CODE | Description W x L (inch) | Material |

| ABS1 | 8″ x 12″ | PP/HDPE |

| ABS2 | 12″ x 24″ | PP/HDPE |

| ABS3 | 14″ x 19″ | PP/HDPE |

| ABS4 | 19″ x 24″ | PP/HDPE |

| ABS5 | 24″ x 30″ | PP/HDPE |

| ABS6 | 24″ x 36″ | PP/HDPE |

Autoclave Packaging Bags Is With Laboteck:

Laboteck is a best reference and leading company in all sectors involved in packaging autoclave bags. Versatility and reliability!

Laboteck -A company in constant evolution, formed by qualified professionals in all areas of activity of the company. Provides a personalized, flexible and quality autoclave sterilization bags to ensure the best comprehensive solution to your customers’ needs.

To find out more about Autoclave Packaging Bags: Call us or contact us!

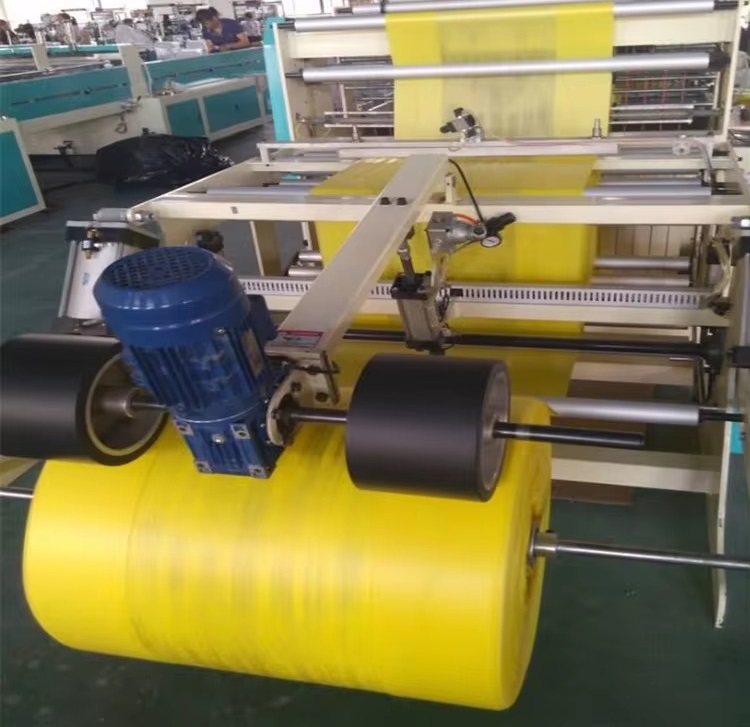

How Autoclave Bags are manufactured in Manufacturing plant.

Request A Free Quote